How Dungster Composters Work

The Dungster composter uses the in-vessel composting method (see In-vessel composting - Wikipedia) to turn tons of food waste, manure and other organics into stable, desirable compost in just 30 days. The Dungster composter efficiently converts the material by thermophilic composting (Wikipedia - Open Source Ecology). This composting method, like all composting, is the key to a sound waste management program. The high heat of the composting step (~150F) “sanitizes” the materials killing fly larvae, pathogens and rendering weed-seeds unable to germinate resulting in ideal organic material used as a soil amendment.

The Dungster composter uses the in-vessel composting method (see In-vessel composting - Wikipedia) to turn tons of food waste, manure and other organics into stable, desirable compost in just 30 days. The Dungster composter efficiently converts the material by thermophilic composting (Wikipedia - Open Source Ecology). This composting method, like all composting, is the key to a sound waste management program. The high heat of the composting step (~150F) “sanitizes” the materials killing fly larvae, pathogens and rendering weed-seeds unable to germinate resulting in ideal organic material used as a soil amendment.

Environmental regulations pertaining to manure, and already enacted, are being more often enforced so to prevent manure piles from running-off and leaching into the public waterways. Composting manure using the Dungster composter turns a foul waste stream into a valuable resource while protecting the environment.

In-vessel composting is a composting method that confines the materials within a vessel. Dungster’s “vessel” is a roll-off dumpster. These dumpsters are never modified when composting and can return to waste hauling at any time. The Dungster aeration kit, with controlled air flow and temperature monitoring, maintains ideal bio-reactor conditions for ideal compost production. Dumpsters are used, “as is”, because they are the most affordable and convenient “vessel” available in all communities both rural and urban. They are mobile, so units can be added and reduced with ease. They are available to purchase, or to rent, (or both) and no permits are required to use a dumpster.

In-vessel composting is a composting method that confines the materials within a vessel. Dungster’s “vessel” is a roll-off dumpster. These dumpsters are never modified when composting and can return to waste hauling at any time. The Dungster aeration kit, with controlled air flow and temperature monitoring, maintains ideal bio-reactor conditions for ideal compost production. Dumpsters are used, “as is”, because they are the most affordable and convenient “vessel” available in all communities both rural and urban. They are mobile, so units can be added and reduced with ease. They are available to purchase, or to rent, (or both) and no permits are required to use a dumpster.

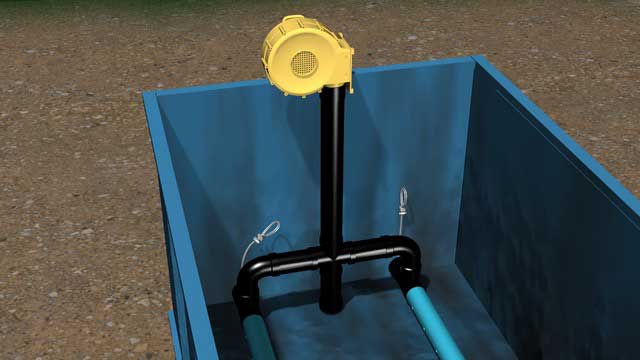

Air is metered in by pipes laying by gravity alone in the bottom of the dumpster fed through a vertical manifold from an outdoor grade blower positioned above. Fresh air is injected from the blower while the exhaust air simply vents through a biofilter. Temperature and moisture conditions are monitored for optimum aerobic decomposition conditions.

With this method, there is no need to "turn-the-pile" and there is no large capital investment. Active composting is done in only one month with curing of the batch to follow.

Aeration pipes are easily recovered for re-use at the end of each batch. View this youtube to see the ease of aeration pipe extraction. Once extracted, these pipes can be placed into another empty dumpster and another batch can be started. The loaded dumpster the pipes were removed from can be emptied or left full and used as a transport vessel for delivery.

Compare Our Process

Dungster in-vessel aeration.

Requirements:

- Small footprint

- Little monthly labor required

- Only 30 days of active composting

- Low costs to start

- A dumpster (as the vessel) costs low four figures when bought used.

- A dumpster (as the vessel) rental costs are low three figures per month.

- Dungster kit costs little to buy or rent (See Buy/Rent page)

- Renting Option; Dungster kit is the only solution available to rent (see Buy or Rent page).

- Weekly operating costs is less than a Starbucks coffee habit!

Other Methods

Windrow and turned pile methods are well known

Requirements:

- Large footprint, mostly due to…

- Long processing time, 3 to 9 months, or more

- Large material handling investment of $20k to $100k

- High labor demands

Aerated static pile and agitated vessel methods, least known methods

Requirements:

- Large up-front capital cost

- Investments into custom assets with no after-market

- Poor scaling flexibility.

- Often requiring building permits and

- Lower return on investment .

The most economical way to turn horse manure into compost Dumpster Kits avaiable for purchase or rental